Jinfeng tell you Process for Manufacturing Toothpaste

The structure of toothpaste

It is composed of wetting excipients, adhesives, washing foaming agents,

flavoring agents, sweetening agents, stabilizers, pharmaceuticals or special

additives. Let Jinfeng Xiaobian to tell you:

Toothpaste classification

In the ordinary toothpaste according to its formula structure can be classified calcium carbonate (stone powder) type toothpaste, phosphorus calcium toothpaste, aluminum hydroxide toothpaste, silica gel toothpaste, etc.; according to toothpaste form can be divided into white toothpaste, color toothpaste, transparent toothpaste, non-transparent toothpaste, color bar toothpaste and so on.

The main raw materials of toothpaste

1, powdered abrasive

2, small washing foam agent

3, wetting excipients

4, adhesive

5, special additives

6, flavoring agent

7, sweeteners

8, purified water

9, other additives: buffer, corrosion inhibitor, preservative

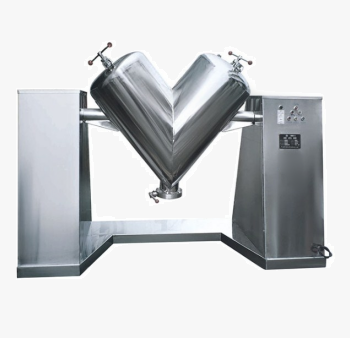

Toothpaste manufacture process

Currently, the most common machine to manufacture toothpaste is the vacuum emulsifying machine. It means to make paste under the negative pressure. Three features are listed as follows. First: sanitary process technology meets the requirement. Second: less consuming condiment, reducing about 10% and saves cost since condiment is one of the most important raw material. There are two ways to describe the process. Single-step manufacturing is the most popular way: finishing at a single-step, that is to say, fixature, paste, homogenizing, vacuum. It has some advantages, including simplifying process, improving sanitary process and is the only way for small and medium enterprises to reform technological process. We will talk about this popular process.

1, Premix and prepare water phrase, oil phrase and solid phrase etc

Oil phrase: premix cementing compound into wetting agent in the CMC tank, based on the formula inventory. Start emulsifying equipment after feeding material.

Water phrase: based on the formula inventory, first premix water soluble auxiliaries into water in the saccharin tank, and then add some certain of sorbitol. Start emulsifying equipment after feeding material.

Solid phrase: premix measured abrasive and other powder into tank according to formula inventory. (Add it into feeder hopper and then vacuum raw material into tank to agitate and mix).

2, Manufacturing Toothpaste

A: start vacuum pump. Feed material when the vacuum degree reaches -0.085MP. Firstly vacuumize premixed water phrase with sorbitol to the reaction kettle; secondly, start frame style agitator; thirdly, suck the oil phrase in the CMC tank to vacuum reaction kettle. Pay attention to slowly feeding material to avoid blister. Switch on high shear mixer and disperser for minutes after finishing feeding materials. Take samples for testing when finishing producing gums. Place it for a while.

B: start vacuum pump. Suck powder into reaction kettle when the vacuum degree reaches -0.085MP. Meanwhile, start Kos high shear mixer and disperser. Switch on inline high speed emulsifying machine after finishing feeding material to grind and homogenize material for second time. Stop machine after several minutes. After cleaning condiment hopper with edible alcohol, add condiment. After finishing feeding, start vacuum pump, frame-style agitator, high shear mixer, disperser and inline high shear emulsifying machine. Paste is completed.

C: prepare paste with compressed air and test it, recording it. Finally into the filling machine through paste delivery pump.

Jinfeng company to "build good, high efficiency, fully in the integration of high performance equipment" as the enterprise objective, adhere to scientific and technological innovation, it is with the person this, for the vast number of users with quality products, has the first-class after-sale service team and win the customer the consistent high praise. E-Mail: sales@jfqgjx.com / joyce@jfqgjx.com

“Recommend”

【editor】:JinfengCopyright:http://www.china-jfmachinery.comReproduced please indicate the source