G-type screw pump ( concentrated Pump)

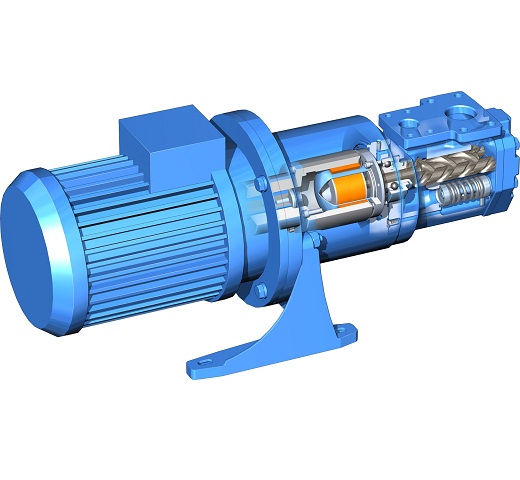

G-type single screw is by circuitous turn engages new pump species displacement principle work, the main working parts are eccentric screw (rotor) and fixed bushing (stator).

Overview

G-type single screw is by circuitous turn engages new pump species displacement principle work, the main working parts are eccentric screw (rotor) and fixed bushing (stator).

Each pump output pressure is 0.6MPa,Head 60m(Water, apply to the transmission medium temperature below 80 ℃ (special requirements up to 150 ℃)

Due to stator is made from a variety of elastomeric materials,So this pump for high viscosity fluid conveyance and containing hard the medium suspended particles or medium containing fiber conveyance,Have general pump the characteristics of the incompetent,flow and speed is proportional to.

Transmission can directly drive couplings,Or use of variable speed motors,Gearbox gear and other devices.

Working principle and characteristics

G-type screw pump,Pump thick is by circuitous turn engages displacement type principle work of the new screw pump,G-type single screw pump,Pump thick main working parts are eccentric screw (rotor) and fixed bushing (stator).

Due to the special geometry of the two parts,Form a separate sealed cavity respectively,The medium uniformity implementation by the axial flow,Internal flow rate is low,Volume remains the same,Pressure stability,Thus does not produce eddy and agitation.

Application areas

1.Environmental Protection: Industrial waste-water,domestic sewage containing solid particles and short fibers of filth and mire of conveying. Especially suitable for oil-water separators plate and frame filter machines and other equipment.

2.Shipbuilding Industry:Wheel bottom clean,Oil water,Greaves,Conveying of oil sewage and other medium.

3.Oil industry:Transportation of crude oil,In recent years, particularly successful mixture deep underground thousand feed of crude oil and water pumping,Thereby greatly reducing the mechanical recovery,When the oil field to the late,Use screw within the formation to increase oil recovery polymer infusion.

4.Pharmaceutical, cosmetic:All kinds of viscous syrup, emulsion, cosmetics and other various ointments conveying.

5.Food canning industry:All kinds of sticky starch, oil, honey, sugar, butter, jam, butter, meat and minced fish its waste conveying.

6.Brewing industry:All kind of fermented sticky liquid boatman, concentrated stillage, dregs food products, all kinds of sauce, paste and bulk solids containing mucus etc..

7.Building Industry:Spraying and Conveying cement mortar, stone mortar, paint and other mushy body.

8.Mining industries:Containing solid particles and dirt Whey and other underground mines within the row to the ground

9.Chemical Industry:Variety of suspensions, oils, various colloids pulp, various binders

10.Printed, Paper Industry:High viscosity of the ink, polymer plastic PVC wallpaper paste and various concentrations of pulp, short fiber pulp conveying.

Scope of application

Screw pump can transport oil, fuel Conveying, transmission oils and polymers for delivery of viscous liquid,Conveying high-viscosity media.

Containing particles or fibers of the media:The particle diameter can be 30mm (not to exceed rotor eccentricity),Fiber length can be 350mm (rather 0.4 rotor pitch),Its content is generally up to 40% medium pit,If the medium solids powder for subtle shape, the highest content of up to 60% or higher can also transfer.

It requires the delivery pressure stable,When the media inherent structure from destruction, the most ideal choice of single screw conveyor.

As can be seen from the above works, screw pump has the following advantages:

(1)The wide range of pressures and flow,Pressure of about 3.4-340 kgf / cm2,

Flow rates up to 100cm3 / min.

(2)The type and viscosity of the liquid transporting a wide range of.

(3)Because of the low rotational inertia force components within the pump, you can use a high speed.

(4)Inhalation good performance, with self-absorption capacity.

(5)Uniform continuous flow, vibration, low noise.

(6)Compared with other rotary pumps, gas and dirt to enter the less sensitive.

(7)Solid structure, easy installation and maintenance.

Screw drawback is that the higher the screw machining and assembly requirements; relatively sensitive to the viscosity of the liquid pump performance changes

Selection principle

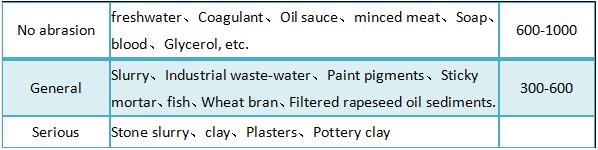

G-type single screw pump thick pump selection based on speed abrasive media

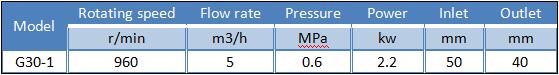

Technical Parameters

Products related to this product / Related Products

- JF-A Vacuum Homogenizer Mixer (Hydraulic Lifting)

- JF-A vacuum emulsifier is professionally designed according to the ointment manufacturing process of cosmetics and ointments etc. Products through introducing advanced technology from abroad. The machine unit is composed of pretreating boiler, vacuum emulsifying and blending boiler , vacuum pump. Hydraulic system, dumping system , electric control system and work platform etc.

- JF-A Small Laboratory Emulsifier

- Small vacuum homogeneous emulsifying machine is suitable for various type of ointment, honey products, small, pilot or a board, it is the cosmetics, pharmaceutical production enterprises laboratory indispensable experimental tool. Equipment has complete function, reliable quality.

- JF-B Emulsion Machine (Fixed type)

- Vacuum homogeneous emulsifying machine is a set of mixing, dispersion, emulsification and homogenization, powder absorbing functions in one integrated system, a control system, but also with the peripheral oil, water tanks, the use of vacuum, heating / cooling system. Is a special equipment for producing medicinal ointment, cream, lotion and other high-grade.

Manufacturing Equipment

- Emulsifying Machine

- Liquid Washing Homogenizer Mixer

- RO Water Treatment Machine

- Perfume Making Machine

- Homogenizer & Dispenser

- Grinding Machine & Mixing Machine

- Laundry Equipment

Packing Equipment

- Automatic Filling and Capping Machine

- Aerosol Equipment

- Hand-made Soap Equipment

- Labeling Machine

- Capping Machine

- Sachet Packing Machine

- Sealing Machine

- Shrink Packing Machine