Rotary Lobe Pump

The product with the help of the working cavity in a plurality offixed volume conveying unit periodic transformation to achieve the purpose of conveying fluid.The original motivation of mechanical energy through the pump directly into the conveying fluid pressure energy the pump flow rate depends only on the working chamber volume change value as well as its in unit time changes in frequency and (in theory) and discharge pressure independent;rotor pumps rely on the two synchronous reverse rotation of the rotor (rotor blade number is 2-8 in the process of rotation)in the entrance to generate suction(vacuum)two rotor rotor chamber is separated into several small spaces in is driven by the trans mission shaft are rotated in the opposite direction medium is conveyed to the discharge port.Thus poses a higher degree of vacuum and discharge pressure so move in circles particularly suitable for high viscosity medium conveying.

Introduction

The product with the help of the working cavity in a plurality offixed volume conveying unit periodic transformation to achieve the purpose of conveying fluid.The original motivation of mechanical energy through the pump directly into the conveying fluid pressure energy the pump flow rate depends only on the working chamber volume change value as well as its in unit time changes in frequency and (in theory) and discharge pressure independent;rotor pumps rely on the two synchronous reverse rotation of the rotor (rotor blade number is 2-8 in the process of rotation)in the entrance to generate suction(vacuum)two rotor rotor chamber is separated into several small spaces in is driven by the trans mission shaft are rotated in the opposite direction medium is conveyed to the discharge port.Thus poses a higher degree of vacuum and discharge pressure so move in circles particularly suitable for high viscosity medium conveying.

Features

1. Gap is kept between the rotors and between the rotors and the pump body no friction long life.

2. Simple assembling and disassembling easy to maintenance and cleanliness easily-damaged parts.

3. High efficiency and energy-saving low failure reliable sealing and low noise.

4. With special material pump could be used for transporting solid granules like sludge and sewage.

5. Capable to pump the viscous material below 2 million cp and and pulp with the solid volume of 60%.

6. Equipped with frequency converter flow can be adjusted at will and can be used as general measurement pump.

7. Flange screw or clamp connection can be selected by customer.

8. Capable of pumping mixtures of gas fluid and solid materials.

9. Heating Cooling pump is off built-in structure with well heat conductivity.

10. Movable type pumps can be used to pump canned medium with vacuum of 0.08 Mpa.

11. Hygienic safety valves can be set at the pump head if customer required.

Application areas

1.Environmental Protection: Industrial waste-water,domestic sewage containing solid particles and short fibers of filth and mire of conveying. Especially suitable for oil-water separators plate and frame filter machines and other equipment.

2.Shipbuilding Industry:Wheel bottom clean,Oil water,Greaves,Conveying of oil sewage and other medium.

3.Oil industry:Transportation of crude oil,In recent years, particularly successful mixture deep underground thousand feed of crude oil and water pumping,Thereby greatly reducing the mechanical recovery,When the oil field to the late,Use screw within the formation to increase oil recovery polymer infusion.

4.Pharmaceutical, cosmetic:All kinds of viscous syrup, emulsion, cosmetics and other various ointments conveying.

5.Food canning industry:All kinds of sticky starch, oil, honey, sugar, butter, jam, butter, meat and minced fish its waste conveying.

6.Brewing industry:All kind of fermented sticky liquid boatman, concentrated stillage, dregs food products, all kinds of sauce, paste and bulk solids containing mucus etc..

7.Building Industry:Spraying and Conveying cement mortar, stone mortar, paint and other mushy body.

8.Mining industries:Containing solid particles and dirt Whey and other underground mines within the row to the ground

9.Chemical Industry:Variety of suspensions, oils, various colloids pulp, various binders

10.Printed, Paper Industry:High viscosity of the ink, polymer plastic PVC wallpaper paste and various concentrations of pulp, short fiber pulp conveying.

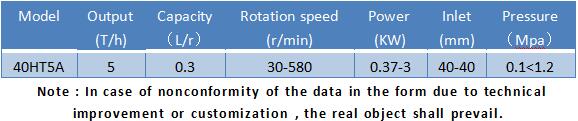

Technical parameters

Products related to this product / Related Products

- JF-A Vacuum Homogenizer Mixer (Hydraulic Lifting)

- JF-A vacuum emulsifier is professionally designed according to the ointment manufacturing process of cosmetics and ointments etc. Products through introducing advanced technology from abroad. The machine unit is composed of pretreating boiler, vacuum emulsifying and blending boiler , vacuum pump. Hydraulic system, dumping system , electric control system and work platform etc.

- JF-A Small Laboratory Emulsifier

- Small vacuum homogeneous emulsifying machine is suitable for various type of ointment, honey products, small, pilot or a board, it is the cosmetics, pharmaceutical production enterprises laboratory indispensable experimental tool. Equipment has complete function, reliable quality.

- JF-B Emulsion Machine (Fixed type)

- Vacuum homogeneous emulsifying machine is a set of mixing, dispersion, emulsification and homogenization, powder absorbing functions in one integrated system, a control system, but also with the peripheral oil, water tanks, the use of vacuum, heating / cooling system. Is a special equipment for producing medicinal ointment, cream, lotion and other high-grade.

Manufacturing Equipment

- Emulsifying Machine

- Liquid Washing Homogenizer Mixer

- RO Water Treatment Machine

- Perfume Making Machine

- Homogenizer & Dispenser

- Grinding Machine & Mixing Machine

- Laundry Equipment

Packing Equipment

- Automatic Filling and Capping Machine

- Aerosol Equipment

- Hand-made Soap Equipment

- Labeling Machine

- Capping Machine

- Sachet Packing Machine

- Sealing Machine

- Shrink Packing Machine