DGYF-500A Induction Sealing Machine

Working principle

Machine adopts the principle of electromagnetic induction heating, by non-contact induction heating, the induction of membrane instantaneously generate heat to melt, firmly stick to the mouth of the bottle, to achieve the purpose of sealing mouth.

Performance characteristics

The machine adopts manual induction head moving sealing operation, simple operation, is provided with over current, overheat protection circuit, stable and reliable work, long service life.

Note:This machine is of no aluminum foil composite film and the vacuum aluminum plating composite membrane is invalid.

Operating instructions

1. The machine is placed in a metal bench, connected to power boot. Note: power line area must ≥0.75mm2

2. Voltage meter readings for the current power supply voltage.

3. Sealing time as the initial value of 1.5 seconds, the operator should according to the sealed bottle sealing time adjustment.

4. The loading sensing film bottles in the induction to cast, press the sealing switch, sealing time countdown, when the time to stop back to the set value, the sealing finish. Note: the center of the bottle mouth with quasi induction head center, otherwise there will be side the other side seal on prison phenomenon.

5. Sealing time adjustment: mouth leak, for light hand seal that is off or the sealing membrane and a pad of paper without separation, the need to increase the sealing time. The bottle mouth sealing membrane wrinkled melt obviously, blistering, must shorten sealing time. Changes in the supply voltage exceeds 10V, requires a corresponding increase or decrease in sealing time.

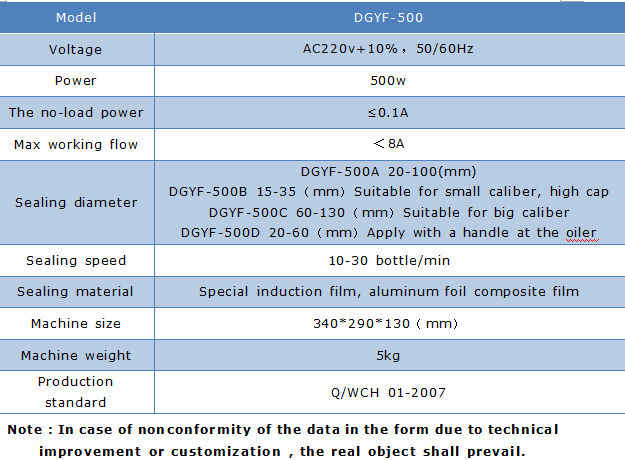

Technical parameters

Products related to this product / Related Products

- JF-A Vacuum Homogenizer Mixer (Hydraulic Lifting)

- JF-A vacuum emulsifier is professionally designed according to the ointment manufacturing process of cosmetics and ointments etc. Products through introducing advanced technology from abroad. The machine unit is composed of pretreating boiler, vacuum emulsifying and blending boiler , vacuum pump. Hydraulic system, dumping system , electric control system and work platform etc.

- JF-A Small Laboratory Emulsifier

- Small vacuum homogeneous emulsifying machine is suitable for various type of ointment, honey products, small, pilot or a board, it is the cosmetics, pharmaceutical production enterprises laboratory indispensable experimental tool. Equipment has complete function, reliable quality.

- JF-B Emulsion Machine (Fixed type)

- Vacuum homogeneous emulsifying machine is a set of mixing, dispersion, emulsification and homogenization, powder absorbing functions in one integrated system, a control system, but also with the peripheral oil, water tanks, the use of vacuum, heating / cooling system. Is a special equipment for producing medicinal ointment, cream, lotion and other high-grade.

Manufacturing Equipment

- Emulsifying Machine

- Liquid Washing Homogenizer Mixer

- RO Water Treatment Machine

- Perfume Making Machine

- Homogenizer & Dispenser

- Grinding Machine & Mixing Machine

- Laundry Equipment

Packing Equipment

- Automatic Filling and Capping Machine

- Aerosol Equipment

- Hand-made Soap Equipment

- Labeling Machine

- Capping Machine

- Sachet Packing Machine

- Sealing Machine

- Shrink Packing Machine