JM-L series Colloid Mill

Overview

JM-L series of colloid mill is the introduction of our factory in West Germany's most advanced technical information and digestion of scientific research projects, domestic original products, is the second generation of wet and ultra-fine processing of the latest machinery and equipment. It is suitable for the homogenization, emulsification, dispersion, mixing, dispersing, grinding and grinding of various emulsions. It is widely used in food (jam, fruit juice, protein milk, dairy products, beverage, etc.) (Pigments, dyes, coatings, lubricants, oil catalysts, etc.) and emulsified asphalt, coal flotation agents, emulsion explosives and other industries.

working principle

The basic working principle of colloid mill is shear, grinding and high-speed mixing effect. Crushing depends on the relative movement of the two gear surfaces, one of which is rotated at high speed and the other is stationary, so that the material between the tooth surfaces is subjected to great shear and friction, and at the same time under the complex action of high frequency vibration and high speed whirlpool So that the material effectively dispersed, emulsified, crushed, homogeneous.

structure

JM-L colloid mill compact structure is simple, small size, the weight of simple operation, by the grinding head parts, the base of rotating parts, the motor composed of three parts. All parts of the contact with the material made of high quality stainless steel, static and static grinding is the key components of the machine, according to the nature of the material being treated, grinding gears are different, the material is made of stainless steel tool steel. The motor is specially designed for colloid mill and is fitted with a flap on the flange cover of the motor to prevent leakage, with connection and split.

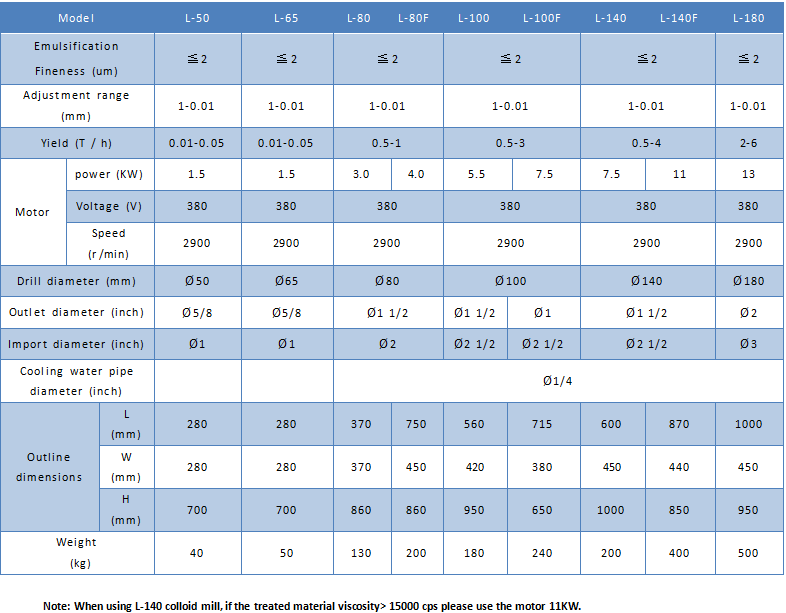

Main technical parameters

Note: In case of nonconformity of the data in the table due to technical improvement or customization, the real objects shall prevail.

Products related to this product / Related Products

- JF-A Vacuum Homogenizer Mixer (Hydraulic Lifting)

- JF-A vacuum emulsifier is professionally designed according to the ointment manufacturing process of cosmetics and ointments etc. Products through introducing advanced technology from abroad. The machine unit is composed of pretreating boiler, vacuum emulsifying and blending boiler , vacuum pump. Hydraulic system, dumping system , electric control system and work platform etc.

- JF-A Small Laboratory Emulsifier

- Small vacuum homogeneous emulsifying machine is suitable for various type of ointment, honey products, small, pilot or a board, it is the cosmetics, pharmaceutical production enterprises laboratory indispensable experimental tool. Equipment has complete function, reliable quality.

- JF-B Emulsion Machine (Fixed type)

- Vacuum homogeneous emulsifying machine is a set of mixing, dispersion, emulsification and homogenization, powder absorbing functions in one integrated system, a control system, but also with the peripheral oil, water tanks, the use of vacuum, heating / cooling system. Is a special equipment for producing medicinal ointment, cream, lotion and other high-grade.

Manufacturing Equipment

- Emulsifying Machine

- Liquid Washing Homogenizer Mixer

- RO Water Treatment Machine

- Perfume Making Machine

- Homogenizer & Dispenser

- Grinding Machine & Mixing Machine

- Laundry Equipment

Packing Equipment

- Automatic Filling and Capping Machine

- Aerosol Equipment

- Hand-made Soap Equipment

- Labeling Machine

- Capping Machine

- Sachet Packing Machine

- Sealing Machine

- Shrink Packing Machine